PRODUCT INFORMATION

FEATURES

- Meets performance characteristics ASTM D8257

- 90-days exposure to UV & weathering

- Slip resistant technology at bottom

- Skid resistant technology at top for improved walkability

- Moisture barrier and energy efficient

- Lighter than standard asphalt underlayment

- Water resistant

- Mold resistant

- Temperature performance -40°F to 240°F

CODES & COMPLIANCES

- ASTM D8257 – Polymeric Roof Underlayment used in steep slope roofing.

- Performance characteristics Exceeds: D5035, D4533, D228, D751, D4798, 0E96, D4869 and D1204

- Miami-Dade County – Approved: NOA #23-0405.01

- Florida Building Code – Approved #FL42168

- Texas Department of Insurance – Listed: ASTM 8257

90-DAYS

EXPOSURE TO UV

SLIP RESISTANT

TECHNOLOGY

WATER

RESISTANT

MOLD

RESISTANT

LIGHTER THAN

STANDARD ASPHALT

UNDERLAYMENT

TEMPERATURE

PERFORMANCE

-40°F TO 240°F

ECONOMICAL

EXTREMELY DURABLE

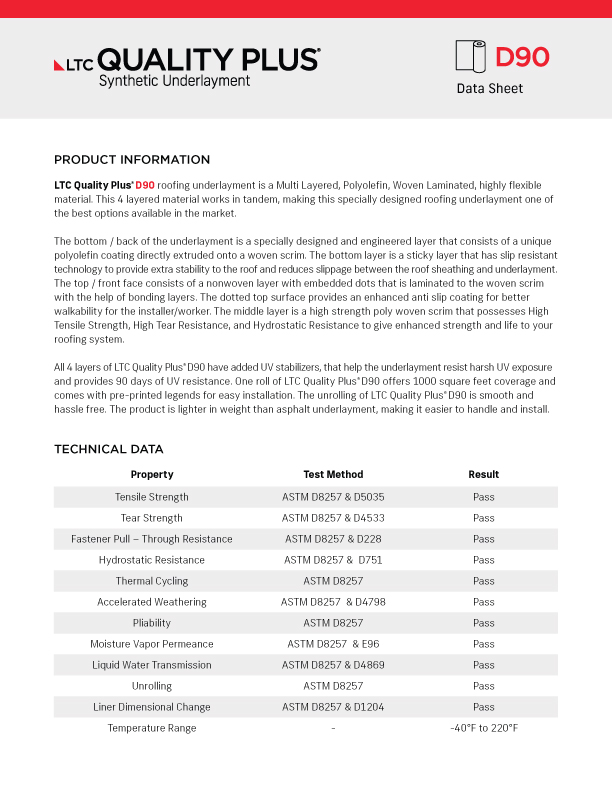

TECHNICAL DATA

| Property | Test Method | Result |

|---|---|---|

| Tensile Strength | ASTM D8257 & D5035 | Pass |

| Tear Streanth | ASTM D8257 & D4533 | Pass |

| Fasterner Pull - Through Resistance | ASTM D8257 & D228 | Pass |

| Hydrostatic Resistance | ASTM D8257 & D751 | Pass |

| Thermal Cycling | ASTM D8257 | Pass |

| Accelerated Weathering | ASTM D8257 & D4798 | Pass |

| Pliability | ASTM D8257 | Pass |

| Moisture Vapor Permeance | ASTM D8257 & E96 | Pass |

| Liquid Water Transmission | ASTM D8257 & D4869 | Pass |

| Unrolling | ASTM D8257 | Pass |

| Liner Dimensional Change | ASTM D8257 & D1204 | Pass |

| Temperature Range | - | -40°F to 220°F |

CERTIFICATIONS & MEMBERSHIPS

GENERAL INSTRUCTIONS

FIELD APPLICATION

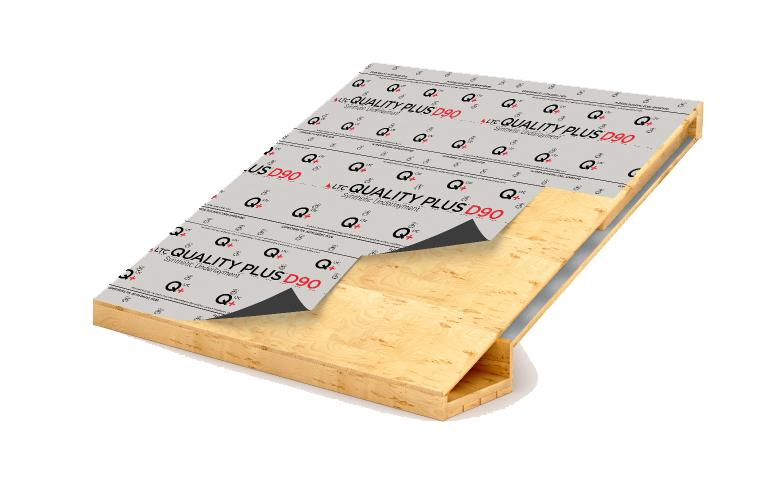

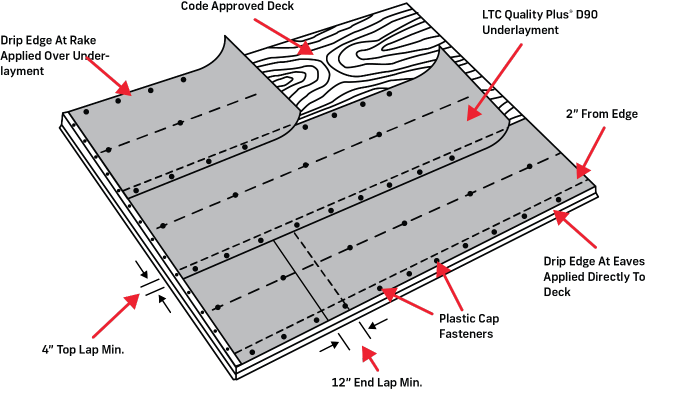

LTC Quality Plus® D90 must be applied to properly ventilated, building-code approved roof decks. Before installing please ensure the roof deck is clean, solid, properly fastened, and free of voids and/or damage.

Begin by unrolling the underlayment from left to right, noting that the printed side should be facing up for installation. Plastic cap fasteners, with a 1” minimum length and 1” minimum cap diameter, must be used to secure LTC Quality Plus® D90 properly. To secure, follow along the indicated fastener placement lines at the top and bottom to space fasteners at 6” O.C. horizontally. Then, follow along the indicated center lines to space fasteners at 12” O.C.

When more than one piece is required to continue a course, overlapping is necessary. The overlaps at the top and bottom should be a minimum of 4”, The fasteners should be placed 2” in from the edge of the top and bottom laps.

The end overlaps should be 12” minimum and fastened vertically at 12” O.C, staying 2” in from the end of the top layer. The plastic cap fasteners should be driven tightly in the surface of LTC Quality Plus® D90, being careful not to cut into the sheet. If any damage to LTC Quality Plus® D90 occurs, it must be repaired before continuing to the next step. ASTM-approved peel-and-stick flashing tape (or equivalent) can be used to repair seams, joints, and tears. Cold-applied adhesives may be used at this point to supplement seal joints, flashings, and overlaps.

For best results, LTC Quality Plus® D90 should be extended at least 12” past all hips and valleys. If LTC Quality Plus® D90 is being installed on decks with less than 4 in 12 slopes, it should be applied in a double coverage method. Here, the overlap of each installed course should be 24”, rather than the normal 4”. It is acceptable to drive the fasteners through both layers to secure.

Always follow the ARMA (Asphalt Roof Manufacturing Association) recommendations for installing shingle underlayment’s and flashings for best roofing practices.